Product development & construction

Sub-processes of construction are model creation and processing as well as the selection of materials and the creation of technical drawings and parts lists.

Reverse engineering and the development of technical documentation.

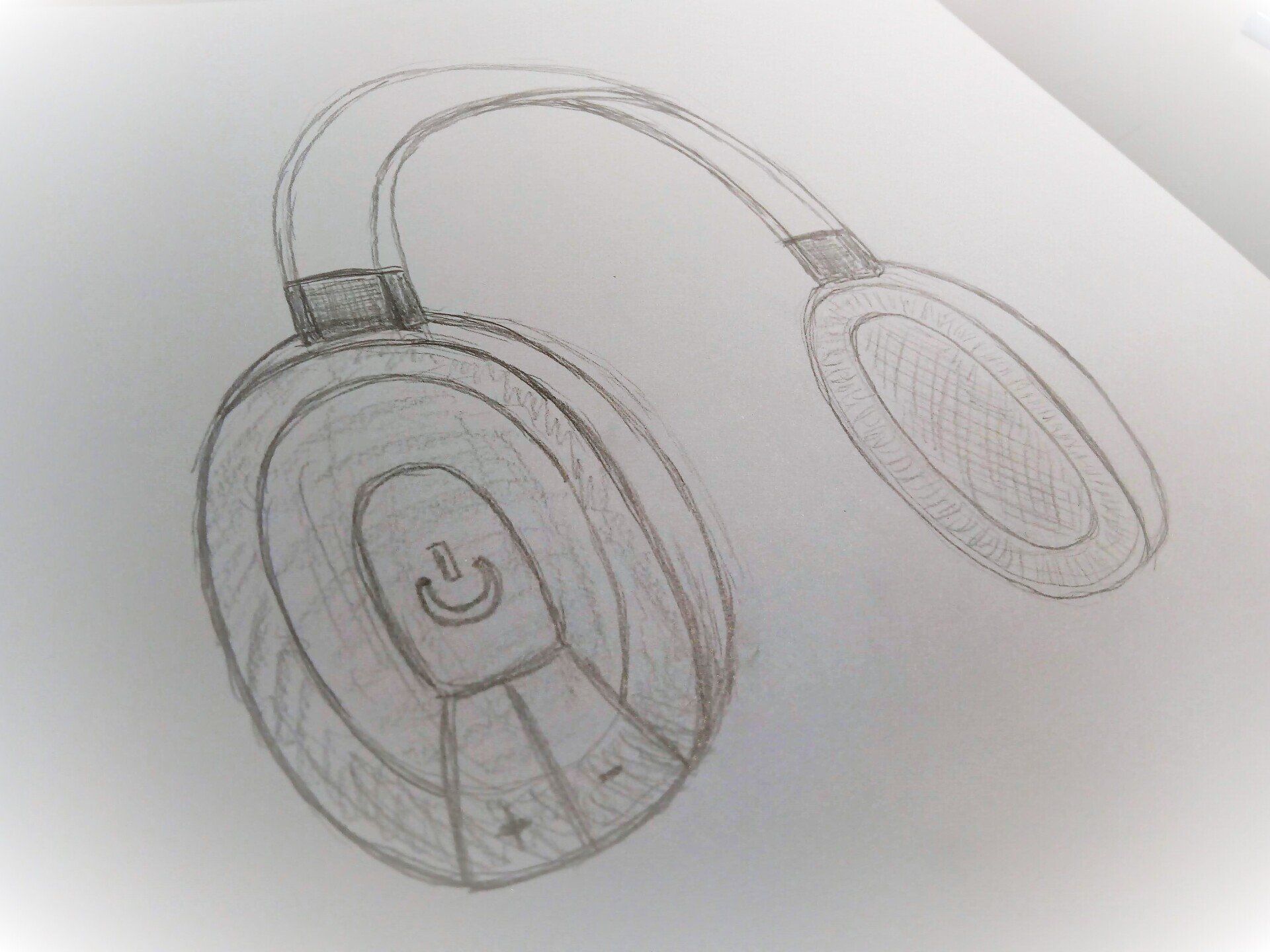

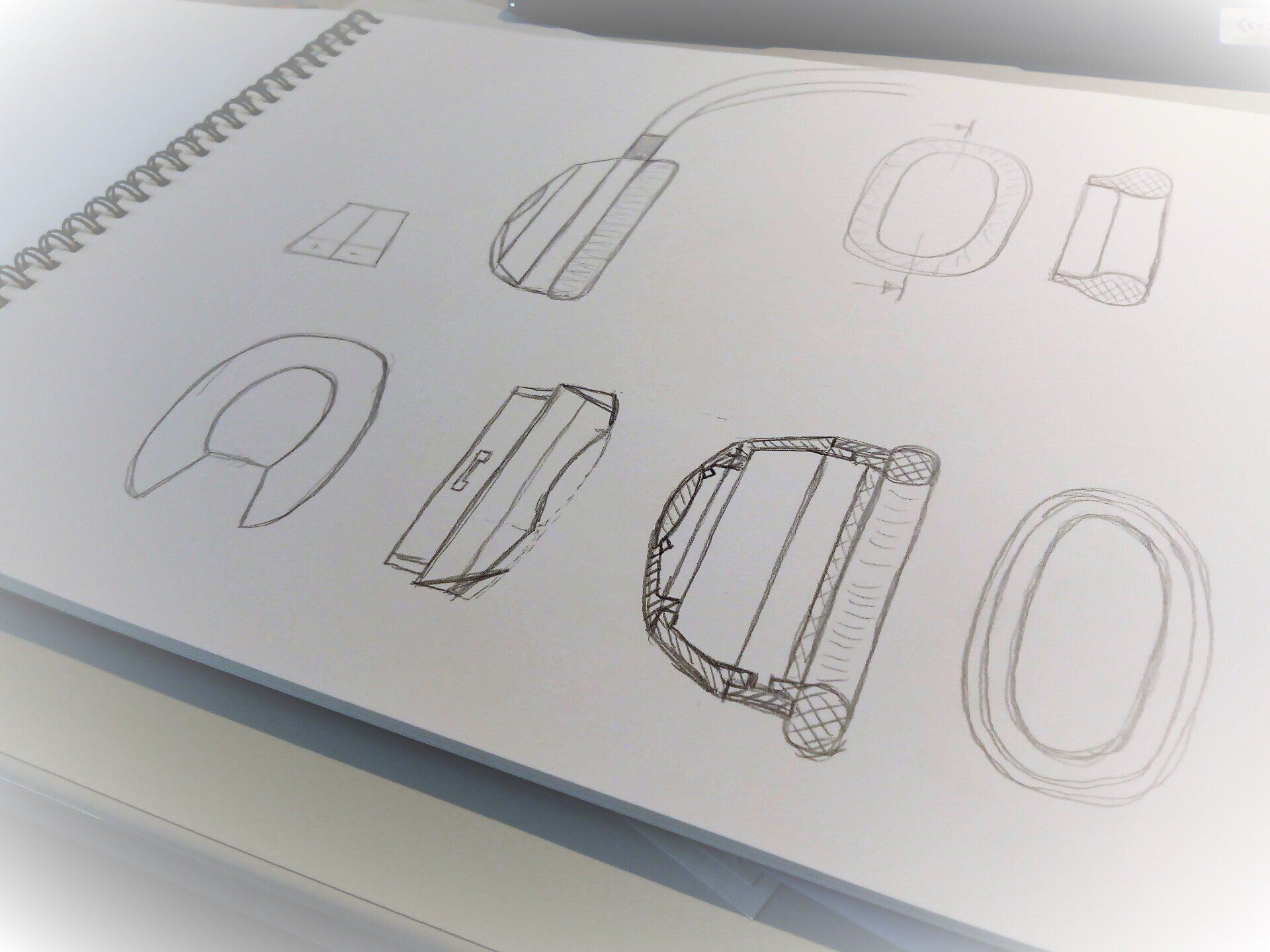

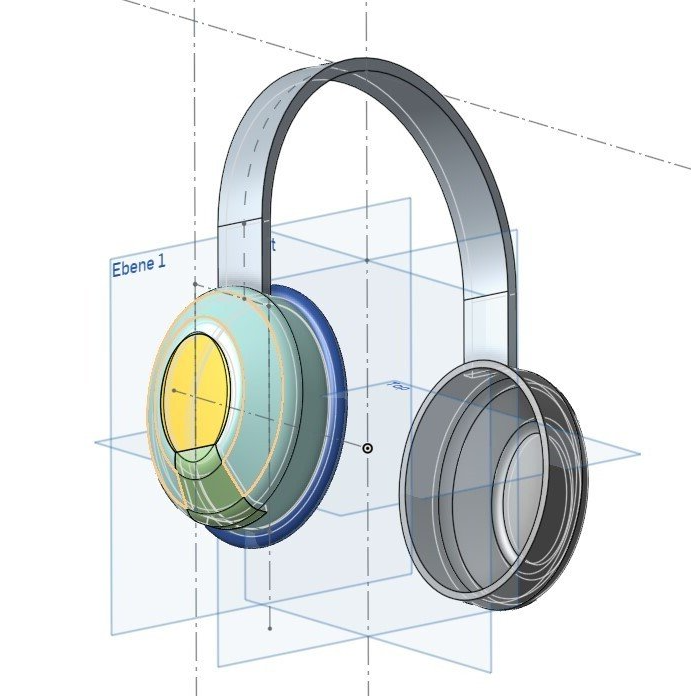

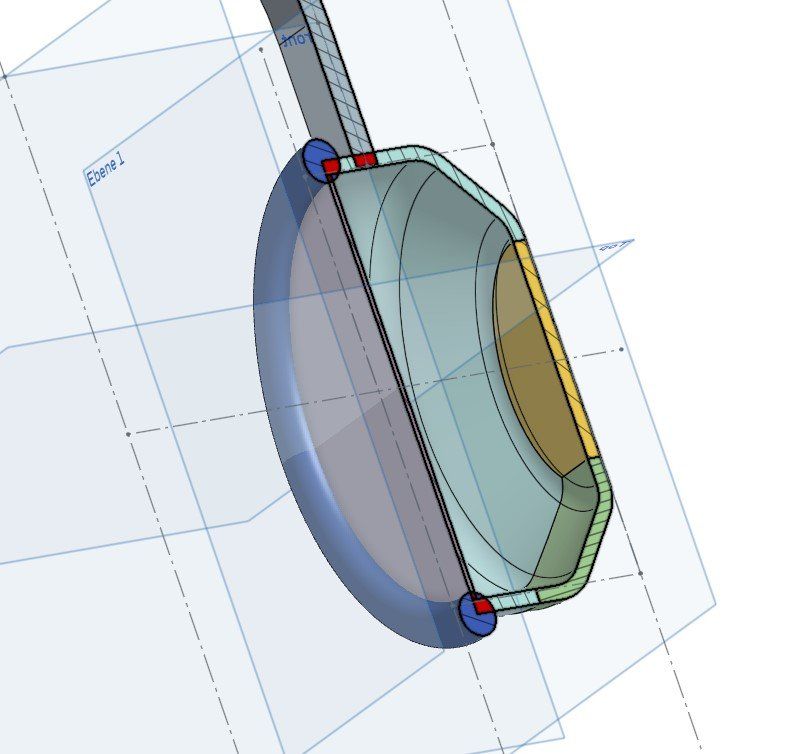

The processes and work that take place in the product development phases are worked out below using the example project of the headphones shown.

Product planning - Development - Construction

VDI 2220, VDI 2221, VDI 2222

Task clarify and design

First, the task and the associated time, content and personnel issues are clarified.

All product design requirements are recorded in a requirements list, which serves as a product-specific basis for carrying out the development task and as a guide, and is the essential control element of the project.

According to all requirements and wishes, functional structures and solutions for sub-functions are developed in the concept phase, partial solutions are combined to form an overall solution, concept variants are specified and evaluated for the subsequent solution selection.

Project planning

Depending on the type of project, the project is divided into different phases and milestones are agreed as milestones. In the product development process, for example, in the four phases - clarify tasks - conceptualize - design - work out. From this, the structure plan and work package descriptions for scheduling and resource planning are created. You will thus receive a reliable planning document for the project management and execution of your project.

Project management

The project management employed assumes responsibility for achieving the project goals. Monitors milestones establishes communication and documentation strategies between project participants. Is the contact person for the project group and takes care of reaching agreement on the project goals to be achieved. She does the planning, control and monitoring of deadlines, costs, quality and performance targets as well as the coordination, management and motivation of the project team.

Product concept

Based on your requirements and wishes for your product, functional structures are determined and solutions for partial and overall functions are developed, evaluated and selected. The first sketches are created and drafts for the CAD construction are derived. After presenting various concepts, the customer can decide which variant is to be pursued further in the design phase and worked out in terms of design and production.

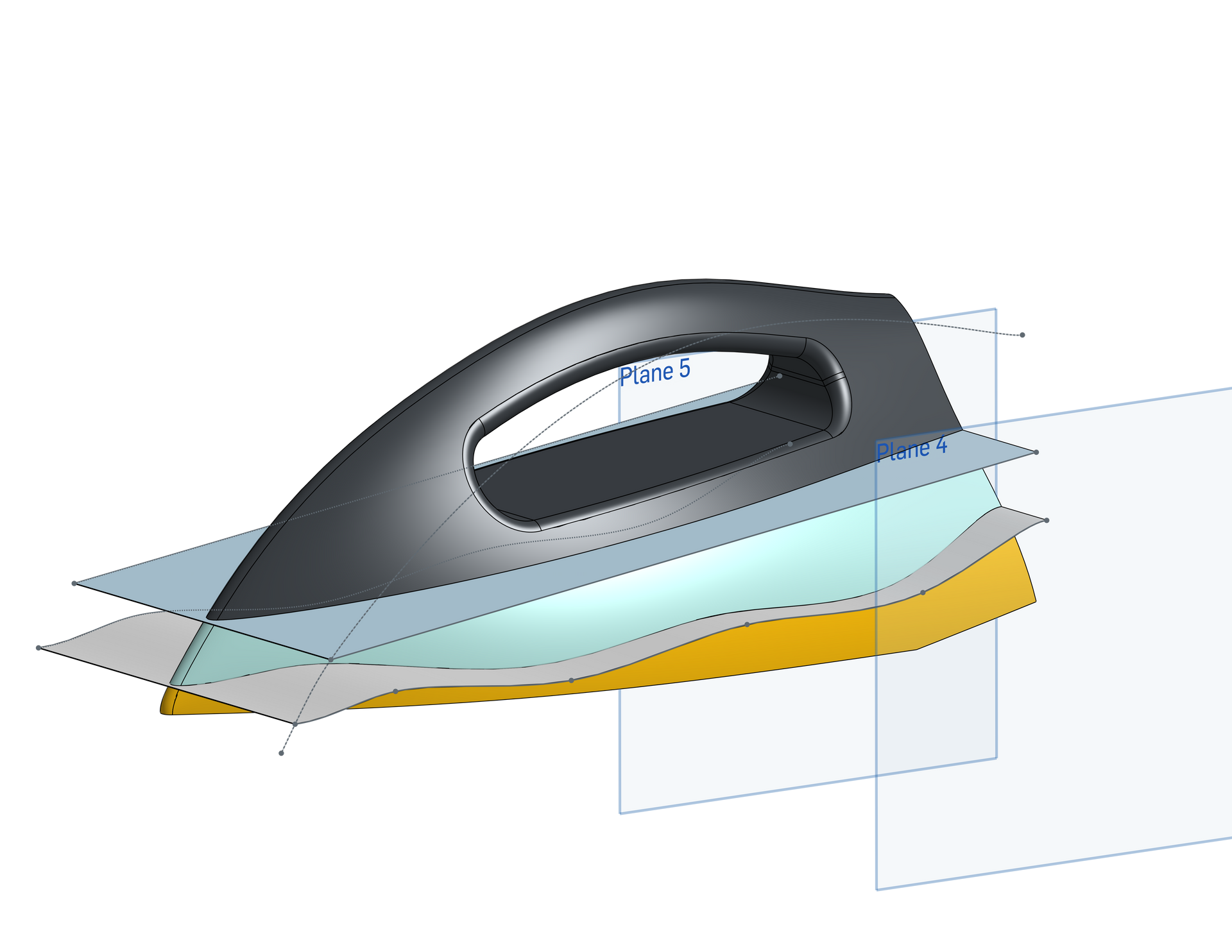

Design

For the design phase, finding a concept provides a basic solution that is essentially defined by the active structure and to a lesser extent by the shape. This results in a true-to-scale design with all the geometric information and material features required for the elaboration.

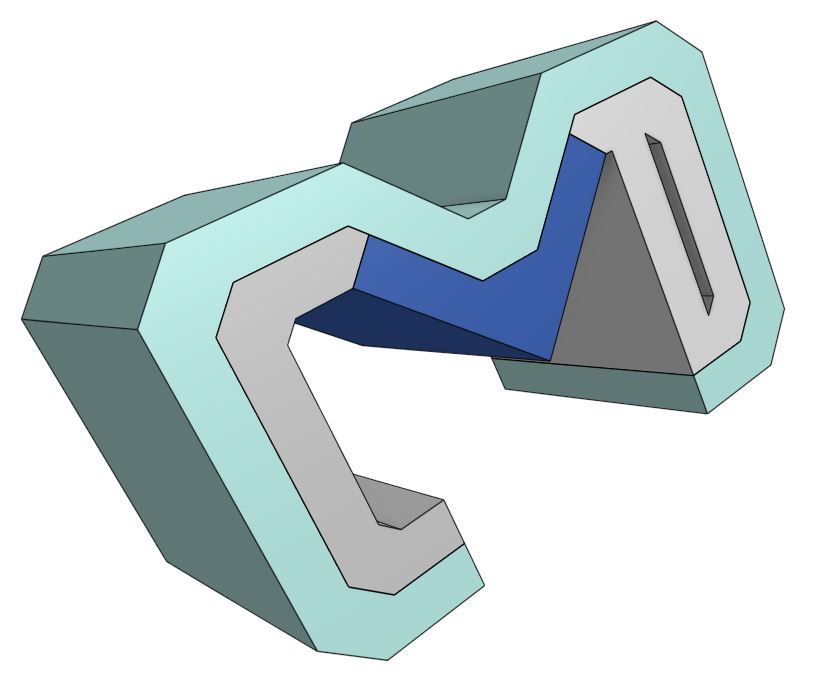

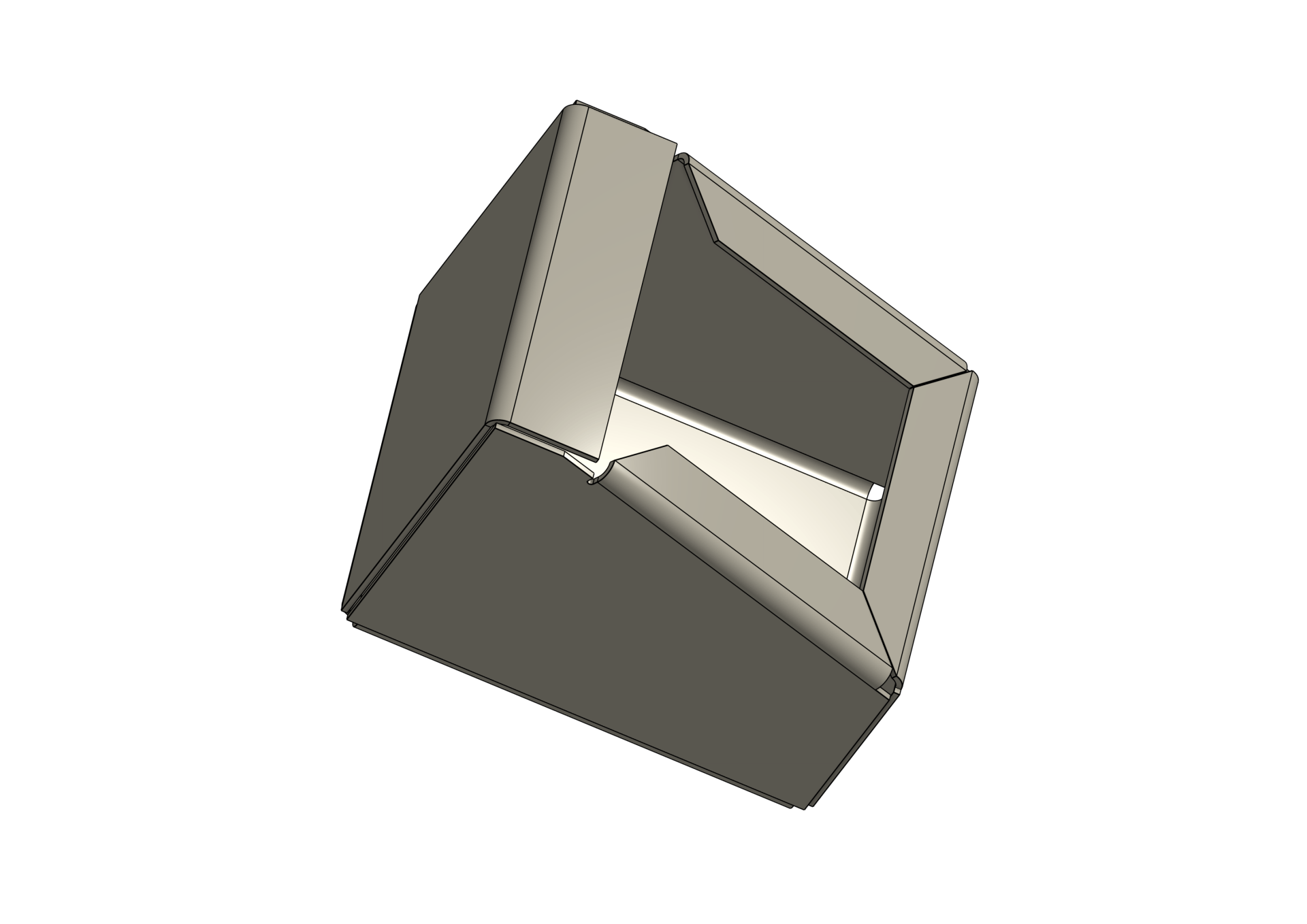

CAD Construction

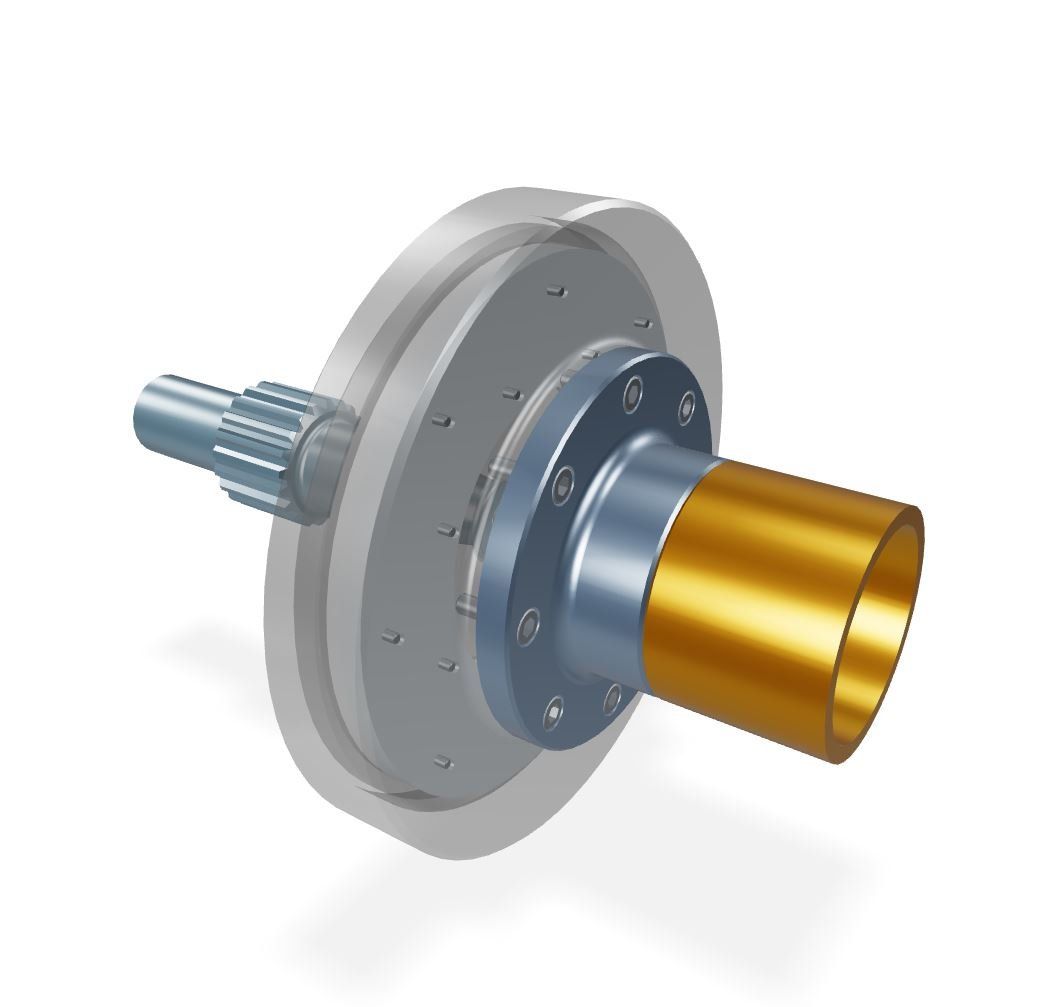

CAD models of individual parts and assemblies can be modeled or imported and redesigned.

Individual parts

- Turned parts

- Milled parts

- Cast parts

- Sheet metal parts

- Plastic parts

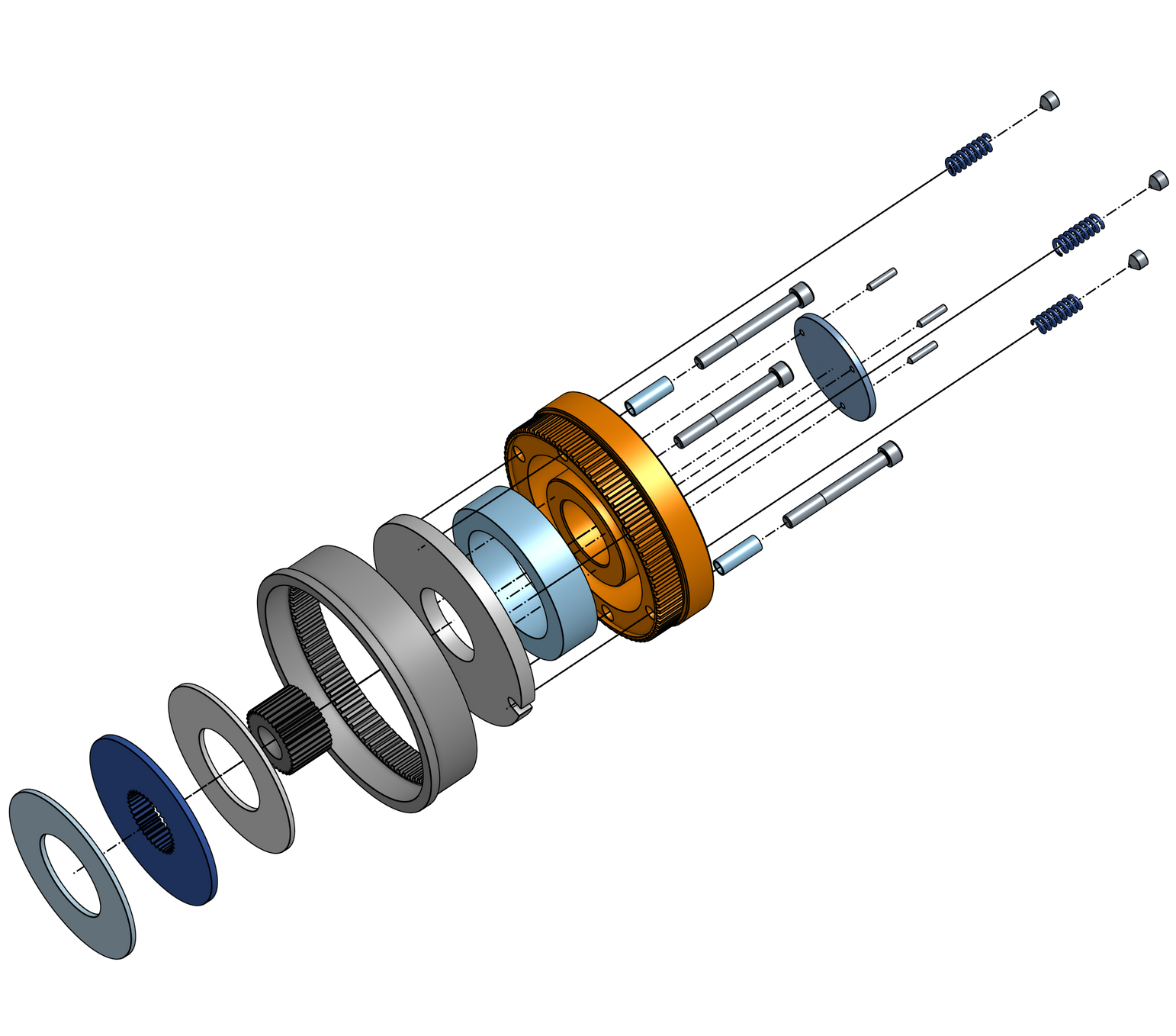

Assemblies

- Assembly

- Functional Animation

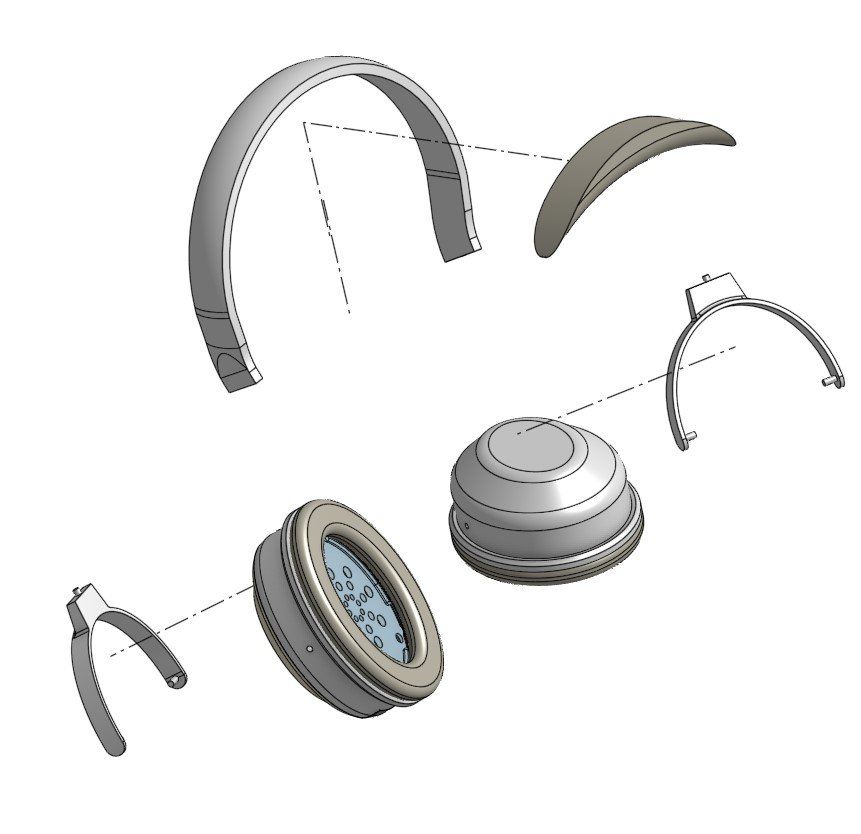

- Exploded View

Material selection

Requirements for the component and function as well as material properties and manufacturing processes provide requirements for the component material to be selected. By formulating component requirement profiles, checklists are created to identify the material requirements for the component. Among other things, long-term stability, component dimensions, temperature and load dependency or the desire for joining processes are taken into account.

Working out

In the fourth and last phase of the construction, the product is technically worked out and defined on the basis of the final design.

Technical drawings of individual parts and assemblies as well as parts lists are created.

Numerous technical requirements for the product such as material, surface quality, fits and test specifications are determined by the engineer and recorded on the drawings.

Technical drawing

Technical drawings are derived or created from the previously modeled component and assembly models or imported 2D or 3D CAD data.

- Single part drawings

- Assembly drawings

- Exploded drawings

- Detailed drawings

- Parts lists

Assembly instructions

The assembly capability of the end product is taken into account as early as the design phase when designing components. Among other things, it must be clarified whether pre-assembly of assemblies is necessary, whether detachable or non-detachable connections are used and whether and in what order operating materials must be added to the product. With the assembly instructions you will receive work instructions described with pictures and text.

Product documentation

As a technical document, the product documentation is the basis for certifications, the manufacturing processes and the production of the product. It is an archivable document with drawings and files which are available for later further developments of the product or for new product variants.

Reverse engineering

By means of reverse engineering, the development and manufacturing process of competing products is reproduced backwards on the basis of the market price and a dismantling of the third-party product. You can thus gain competitive strategies of the competition but also suggestions for your own technical improvement potential.